PCD Dies and Tools

PCD Dies

Important guidelines for Wire Die end-users

- For delicate nonferrous wire, abide by the maximum recommended hole diameter. Hard ferrous cord’s diameter cannot exceed 65% of this

- To extend the life of the die, recut or repolish it after noticing worn rings where the twine would normally be

- Filter the lubricant to remove any metallic particles to increase die life and lubricant glide

- Shorten the bearing to enable faster drawing

- When drawing iron, plated wires, and stepped forward cord floors, use finer grain die blanks

- Use finer grain die blanks to provide longer die life and improve wire dimensional control when drawing big sizes of nonferrous wire

- When drawing Tungsten and molybdenum wire at high temperatures, maintain a low environment to minimize the negative effects of oxidation and maximize die lives

- When using multiwire drawing machines, use matching elongation die units.

PCD Tools

Varun Udyog manufactures Sintered Diamond pointed tools, Inserts, Reamers, etc. PCD blanks are employed for twisting, grooving, grinding, and boring on nonferrous and non-steel materials.

Advantages:

- Significantly faster-cutting speed and feed costs than traditional reducing equipment.

- Higher material removal costs, advanced cycle times, imparting more components per shift.

- Highly improved workpiece quality, excellent dimensional control, consistent surface finishes, and decreased scrap

- Longer device life leads to increased machine up-time, providing additional manufacturing capacity without investing in new equipment.

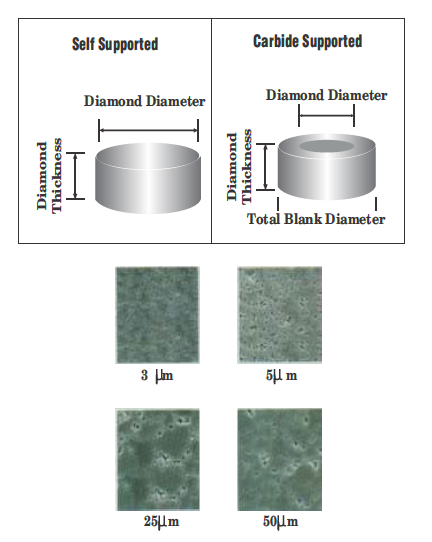

Polycrystalline Diamond Dies

A higher polish translates into a less tough drawing operation and a better nice finish of the final result.

The technical advice for the preference of PCD blanks, with a broad preference of possibilities customized to each use (copper, aluminum, steel, alloys, etc.), while also considering your specifications and performance needs.

Consistency of the geometry and a high stage of floor polish are two things that need to be done to get the best results possible in terms of floor finish, tight tolerances, dies performance, and protection of your lubricants. In addition to this, people are living longer lives noticeably.